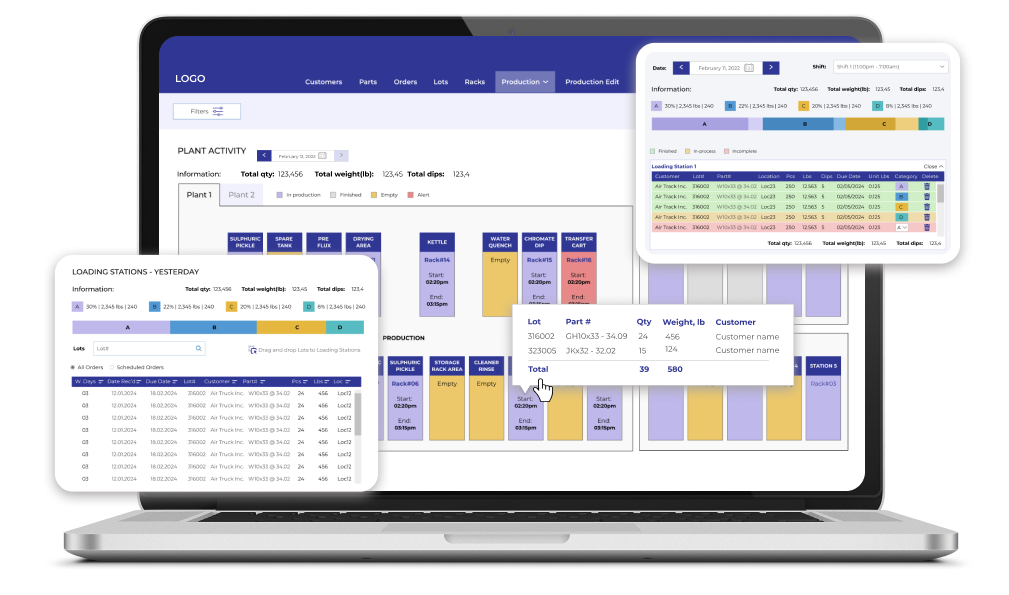

Custom Manufacturing Software That Revolutionizes Your Manufacturing Workflow

Streamline your manufacturing process with custom manufacturing software. Optimize and improve the efficiency of your workflow with software designed exactly for your needs

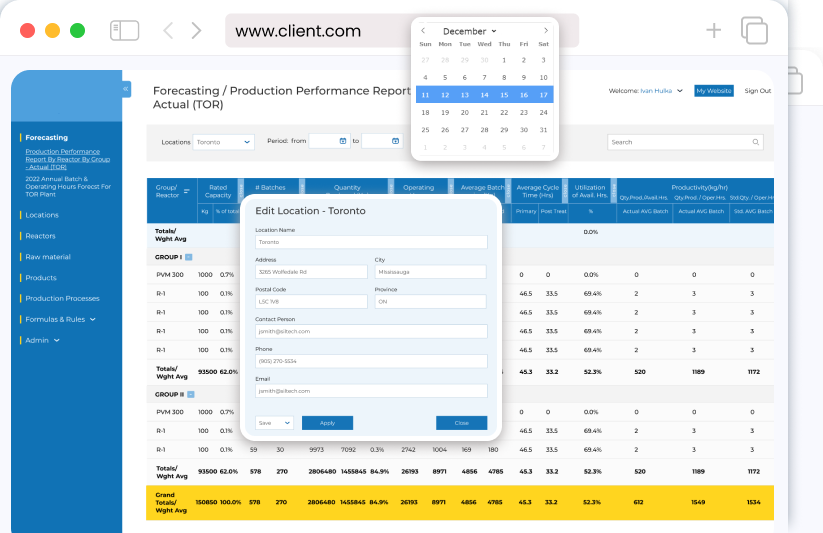

As complex as the manufacturing process can be, managing it shouldn’t be so. Our manufacturing software solutions help streamline the manufacturing process for small, medium and large scale enterprises through a set of highly-efficient features. Manual tasks automation, effective manufacturing planning and scheduling, access to real-time manufacturing floor updates as well as access to bird’s eye view of the entire manufacturing process - all these features can be included into the custom manufacturing software built to suit your specific needs.

No production process is alike, and we at Vestra Inet understand this. For this reason, we offer our clients fully-customized manufacturing software solutions that cater to their unique needs and requirements. Custom manufacturing software acts like a control panel that simplifies complex multi-level manufacturing processes, allowing you to oversee all the stages of the manufacturing process.

Optimize Manufacturing Workflow

Improve Production Process Efficiency

Operational Costs Reduction

Centralize Control

Maximize Profits

Performance Monitoring

Our manufacturing software solutions are specifically designed to provide you with full control over your production cycle. With customizable automation features, you can optimize multiple stages of your manufacturing process and improve operational efficiency. Custom manufacturing software offers a centralized view of all processes, allowing you to make informed decisions, resulting in significant cost savings and increased profits