Custom Quoting Software for Fabrication Shops: Beyond Spreadsheets and Guesswork

|

Precision is everything. That is the motto every fabrication business is built on, and its quotes are not any different. Far from a clerical task, you know the value your quotes carry. They can either turn the tide in your favor, or dry up your shores.

Your customers need fast, accurate, and competitive quotes. Deprive them of it, and they will likely take their business elsewhere. Sadly, quoting is rarely a straightforward affair for fabricators. Factors such as fluctuating material costs, varying labor estimates, and tolerances or scrap factors can make or break margins.

Relying on spreadsheets or generic quoting tools may feel like a “good enough” way to tackle these challenges, but they often make it worse by introducing hidden risks in the form of errors, delays, and lost revenue.

So-called “small errors” such as a misplaced formula or outdated material costs can spell catastrophe, leading your quote to erode profits or to put you out of the race altogether. That is why you need to turn to custom quoting software. Especially if growing your business is in the cards.

Breaking the chains of a one-size-fits-all solution, fabrication quoting software can handle the complexity of your specific workflows, ensuring you get accurate quotes that churn profits.

Common Quoting Challenges In Fabrication Shops

We know that quoting is not a plug-and-play process for you. It is a high-stakes exercise that needs to strike the perfect balance between accuracy, speed, and competitiveness. That said, every job your business gets brings with it a unique set of requirements. Unfortunately, variables can stack up quickly, leading to more challenges such as:

Variable costs and surcharges

The prices of steel, aluminum, and special alloys tend to fluctuate daily. Using static spreadsheets to keep track of them is not only cumbersome, but also unrealistic. Spreadsheets will not give you the real-time cost estimates you need to create accurate quotes. Neither will they be able to factor in vendor surcharges or delivery fees. You need a more efficient system (read: custom quotation software) to do both.

Labor time estimation for custom parts

Even if two jobs seem similar on paper, they are likely to differ in terms of machining techniques or time taken to weld. The only way to make safe labor estimates is to check historical data for similar jobs – an impossibility if you use spreadsheets or half-baked quoting solutions. The result? Underquoted or overquoted labor hours that hurt your profitability and competitiveness in the market.

Waste factors, tolerances, and yield losses

Scrap, tolerances, and nesting efficiency are part and parcel of each fabrication assignment. Accounting for these nuances in spreadsheet-based quotes can lead to many inaccuracies, including unexpected costs once the work is in progress, as well as optimistic yield assumptions. These can throw your budget off-track, forcing you to revise your quote, thus leaving clients unhappy.

Handling customer-specific requirements or revisions

Often the need to revise quotes comes from having to factor in client-specific customizations and special rates. Making these changes on emails, printouts, and spreadsheets creates a confusing trail of paperwork. Version-control chaos increases the risk of sending out quotes with outdated specs.

Spreadsheet version conflicts and inconsistent formulas

Got multiple people working on the same quote? Frequent editing of shared files means increased risk of broken formulas, adrift numbers, and circulation of different versions with no way to know which is the latest one. With inconsistent pricing added to the mix, you cannot be too sure if the quote leaving your shop is accurate and ready to close deals.

We have seen several quotes with titles such as “Shop_Quote_v3.xlsx” and “FINAL_FINAL_v5.xlsx” to know there is trouble lurking within the tabs of these sheets. Shop floor quoting needs something faster, and more reliable.

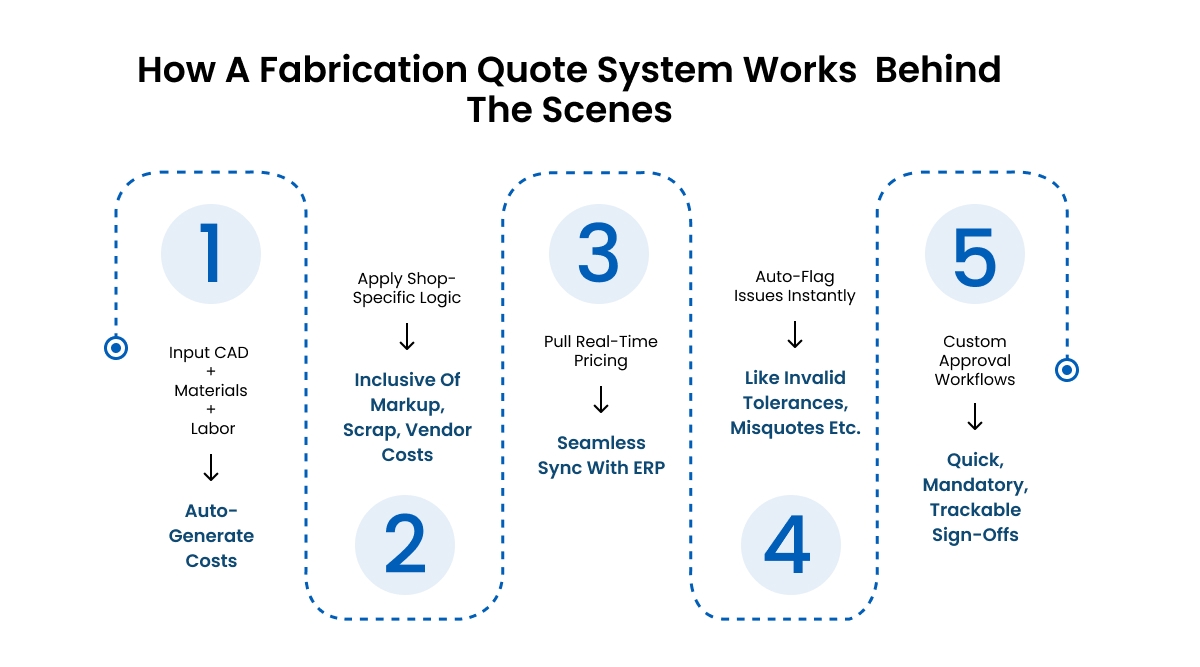

How Custom Quoting Software Solves Issues Fabricators Face

With 20 years in the industry, we can confidently tell you that custom quotation software is the solution. Designed to eliminate fabrication quoting errors, it can bridge the gap between fluctuating steel prices, unique part geometries, and complex finishing requirements, ensuring the moving parts of every quote align into a sensible, accurate whole.

Dynamic cost calculator for material and labor

Metal fabrication quote software is not static. Unlike spreadsheets, its dynamic nature can allow for the automatic application of material rates. It also makes room for accurate labor costs by modeling them on the type of machine used, the time taken to set it up, and operator skill. You can say goodbye to guesswork with quotes that reflect real input.

Built-in CAD/Blueprint input capabilities

The starting point of most, if not all, fabrication jobs is a CAD file or a blueprint. Needless to say, manually entering specs into a spreadsheet is a clerical nightmare. Capable of importing drawings directly, custom software can give you precise tolerances and dimensions. The system can also generate estimates that account for true geometry, cut lengths, whole counts, or weld seams, thus saving you hours of time.

Custom logic for markups, scrap rates, and overhead

Your shop, your rules. Your system should function as per your pricing rules — from markup logic to scrap recovery rates. Custom software embeds these rules into its engine, making manual errors a thing of the past. As long as you get your presets right, the logic will run automatically and consistently with no human intervention required – be it adding a 10% markup to stainless steel tasks or accounting for yield losses during laser cutting.

Real-time sync with supplier pricing

Volatile material costs can be tough to tackle unless you use custom software. Syncing directly with your supplier catalogs, it can automatically update your quotes with accurate pricing, reflecting the latest updates to steel surcharges, aluminum costs etc. Eroded margins are out of the picture in such cases.

Approval workflow and role-based access

Quoting solutions for custom metal parts can let you preset approval workflows that are unique to your shop. Workflows can be based on job size, priority level or client type. You can also set role-based permissions to prevent unauthorized edits, implement strict checks, and have sound audit trails for greater transparency. Having a structured and compliant workflow is key to efficiency.

Steps To Transition From Manual To Automated Quoting

Though shifting from Excel to a dedicated fabrication quoting software is a big leap, it’s not without its benefits. Designed to help your business thrive, it frees you from the error-ridden ways of manual processes.

However, if you find the switch daunting, we suggest taking it step-by-step. In our experience, fabrication shops that treat the move in a structured fashion have a greater chance for success. Here’s a basic transition wireframe we have developed that you can follow:

1. Audit your current quoting workflow

Create a detailed outline of your quoting process and map its journey from request to delivery. Flag points of error, track time taken per quote, and count the average number of revisions needed. The biggest gaps reveal the scope for the most major wins.

2. Identify high-risk quotes

Quotes that are most likely to result in mistakes typically involve custom jobs, emergency requirements or material-intensive tasks. Your shop floor quoting automation should focus on tackling these categories of quotes first.

3. Define your quoting rules

Variables are an integral part of fabrication – be it in the form of machine run-time, tolerances, scrap or markups. Spreadsheets are rarely able to represent these variables accurately, which is why it is critical that you document the logic that defines these variables clearly so it can be embedded into your estimating software.

4. Select the right modules

Software development companies tend to offer highly feature-packed quoting systems. The good ones give you the flexibility to choose the features your fabrication shop needs the most. For example, if CAD/blueprint input is a must-have for you, you can request that as a feature. You can pick and choose modules and ensure they include or exclude ERP sync, BoM generation, approval workflows and more. You do not need to stick to a rigid template.

5. Build, test, and train

Before rolling out your quoting solution for custom metal parts, test the system on real jobs. If you notice hiccups, request the development company to iron them out and to refine your system until it functions as needed. Also, train your team diligently so they learn how to use and trust the software. Early and successful adoption is key to software ROI.

Your goal with a custom quoting system should extend beyond digitizing spreadsheets. It should be about safeguarding your fabrication business while laying the foundation of accuracy, speed, and higher profit margins.

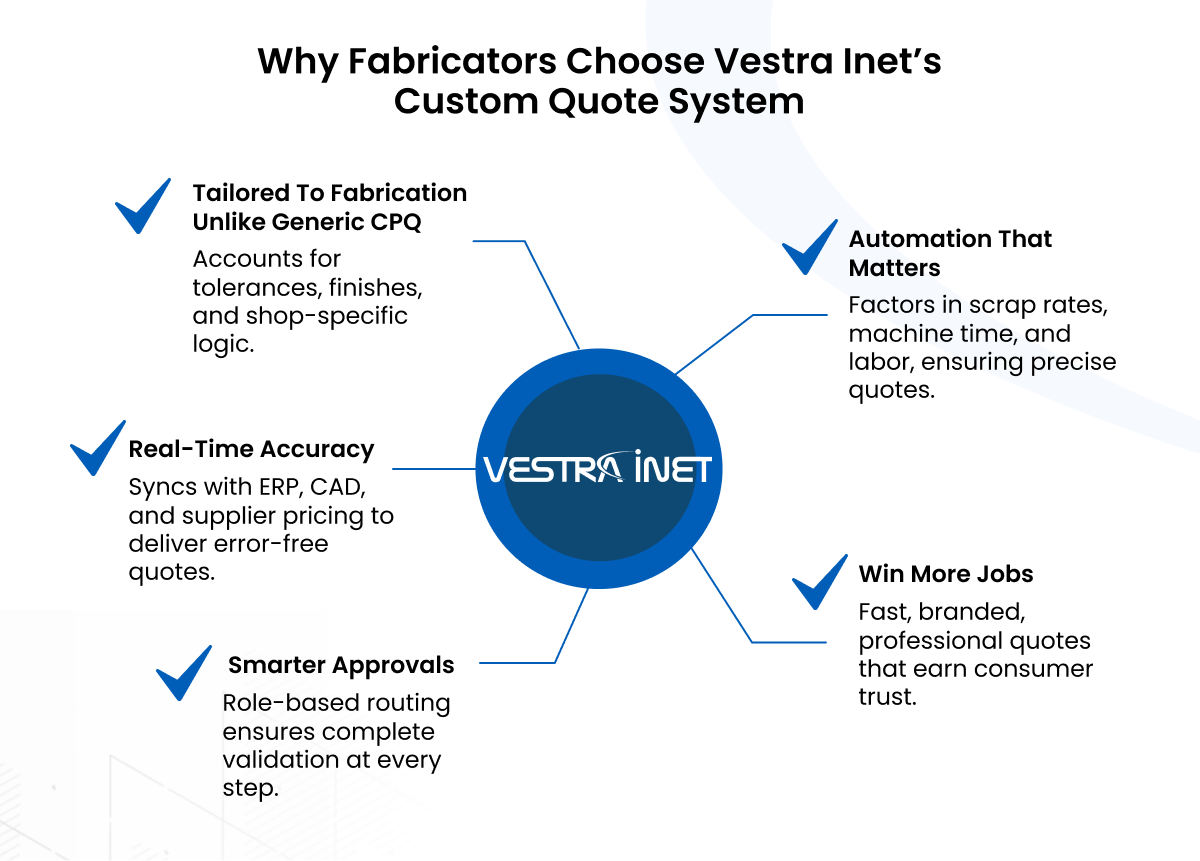

Why Vestra Inet’s Quotation Making Software Fits Fabrication Workflows

Not all off-the-shelf solutions are capable of handling the realities of a fabrication shop. Your business often requires a more nuanced tool rather than a run-of-the-mill SaaS software.

The problem with generic tools is that they are unable to account for custom finishes, tolerances, or real-time supplier price variations. That’s why at Vestra Inet, we build fabrication quoting software that actually reflects the goings-on of a typical fabrication shop.

Custom fields for tolerances, materials, and finishes

“Standard parts” are rarely the norm for any job in a fabrication shop. Quotes can vary wildly depending on minute specifications such as the thickness of the metal, bend radius, plating or other secondary operations. At Vestra Inet, we build custom systems where each of these variables can be embedded into the quoting engine, eliminating the need for workarounds.

Approval routing for engineering and production teams

Although the sales department primarily handles quotes, approvals can be cross-departmental. Engineers are involved in validating feasibility, while production managers confirm machine capacity. Furthermore, higher-ups might be involved in overall approval too. Our metal fabrication quote software adapts to your unique approval chain so no quote moves forward until it gets the appropriate sign-offs at each level.

Logic-based modules built for shops, not just software users

So many of our clients have come to us complaining about how off-the-shelf systems fail them. Treating fabrication like a catalog business, these systems simply lack the modules your business requires to function in its own unique manner. On the flipside, estimating software for fabrication shops that we’ve built can factor in scrap rates, setup times, and shop-floor scheduling rules, thus providing you with truly customized quotes that are both realistic and profitable.

Seamless integrations with CRM and CAD

Most fabrication shops use CRM systems and rely heavily on CAD data to carry out jobs. We design our software to ensure it syncs with both, thus saving you the time and effort while supporting shop floor quoting automation from design to delivery.

At Vestra Inet, it is our mission to create quoting systems tailored to fabrication workflows, covering every step of the way – from raw material sourcing to machine time estimation and markup logic – giving you fast, precise, and professional quotes that are ready to win clients and drive profits.

Final Thought: Win More Jobs With Smarter Quotes

For a fabrication shop, speed and accuracy are secret weapons that can help you stay relevant and competitive in the long run. But if you rely on spreadsheets for quoting, both speed and accuracy take a hit, introducing costly mistakes while eroding client trust.

Vestra Inet’s fabrication quoting software can save you from this conundrum. Tailored to your workflow, it generates quotes with precise pricing and automated approvals, thus inspiring consumer trust. Contact us if you want quotes with fewer revisions, faster turnaround times, and a stronger win rate. We can take the guesswork out by building a smart system for you that will reflect how you really work.

FAQs

1. What is fabrication quoting software?

Fabrication quoting software is a solution that solves the unique quoting challenges fabrication shops face. It should automate cost estimation for metal parts, assemblies, and custom jobs. It should also account for waste factors, tolerances, labor, and shop overhead, allowing fabricators to generate accurate quotes faster.

2. How does quoting software handle material price changes?

Custom quoting systems come with the ability to sync with CRM platforms, inventories, and supplier databases. This allows them to pull live pricing, ensuring generated quotes feature current prices of steel, aluminum or specialty alloys.

3. Can I customize quoting logic for my fabrication shop?

Yes. Custom software’s logic can be tailored to replicate your unique workflows. From scrap adjustments to customer-specific discounts, fabricators get the flexibility to match their shop prices and embed custom logic into our quoting system.

4. Does quoting software connect with CAD or ERP tools?

Yes. Advanced solutions can directly pull specifications from CAD drawings as well as sync with ERP, CRM, and inventory platforms for live inventory updates, job costs, and approvals, thus streamlining shopfloor quoting automation.

5. How long does it take to execute a custom quote system?

Implementation windows depend on the software’s complexity and the client’s unique requirements. That said, fabricators can get a working system within weeks, which their teams can start using to reduce manual quote errors and boost accuracy and efficiency across the board.

Author Bio

Andrey Wool

Helming the operations at Vestra Inet, Andrey has over 20 years of leadership experience in the ERP industry. Having successfully launched 550+ software projects across a diverse set of industries, Andrey continues to transform the way businesses function with pioneering custom software solutions. His in-depth knowledge of sectors such as manufacturing and distribution has helped him curate actionable solutions that eliminate bottlenecks and pave the way for sustainable growth.