How Integrated Quoting Software Unites Sales and Operations in Manufacturing

|

Success or failure is not purely a matter of quality in manufacturing. Ultimately, it’s the proposal you send out to your clients that decides which way the scales will tip.

That is why it is never a good idea to let your sales and operations teams work in silos. Quotes that are out of touch with the realities of your operations can suffer from errors.

Truth be told, even the smallest error in this regard can quickly snowball into a full-blown loss-inducing catastrophe. We are talking inefficiencies, missed deadlines, and poor margins.

As difficult as it may sound, you can still escape the consequences of a poor quoting process by overhauling it from the ground up.

Integrated quoting software is your key. Designed to bridge the divide between sales and operations, it effortlessly connects your ERP and production systems in real-time so you get accurate and transparent quotes no matter what.

In this blog, let us show you how it can be your key to smarter quoting and faster order fulfilment.

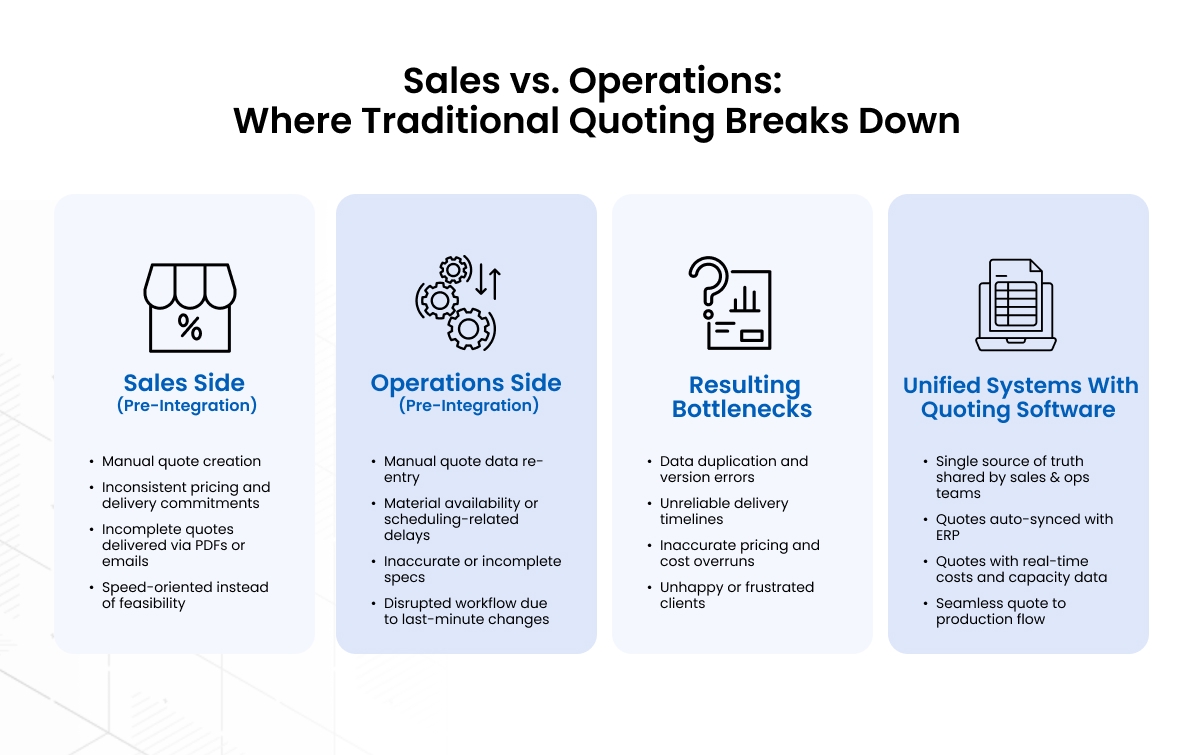

The Disconnect Between Sales & Operation In Manufacturing

It’s striking how a manufacturing business’s sales and operations team work towards the same goal but in completely disparate ways.

While the sales team tackles the client side of things – from drafting proposals to winning deals with quick responses, the operations team works hard to complete jobs as per available capacity and stipulated timelines.

However, friction arises when they do not work in sync, and that is what can cost your business time and money.

Common communication gaps between teams

The manual transference of quote details from the sales to the operations department can result in the passage of incomplete or outdated information. This means that now your sales team is caught in a cloud of confusion about which materials to use, what the timeline is, and how much labor is required to complete the job. Delays are inevitable.

Delays caused by manual quote handoffs

Spreadsheets or standalone tools do not make quote generation any easier. Information from approved quotes has to be manually re-entered into your ERP platform, which naturally creates a breeding ground for delays and errors.

How disjointed systems impact profitability

By now, you can see how wide the gap between your sales and operations teams can be when you depend on manual quoting methods. The resultant inefficient scheduling is only half the problem. The other half lies in misaligned pricing and inconsistent cost tracking. Your sales team might end up over-promising, and your operations team might not be able to deliver, leaving you with frustrated clients and reduced margins.

The truth is, quoting is not merely a sales task. It’s a vital function that affects company-wide operations. That’s why you need a custom quotation system. So you connect all systems and nip inefficiencies and inaccuracies in the bud.

What Is Integrated Quoting Software?

Ready to explore the world of integrated quoting software? Let us walk you through it, section-by-section, so you have a fair idea of what it is and what it does.

Definition and core capabilities

Integrated quoting software is designed to connect your sales, operations, and production systems into a unified whole, thus preventing silos that hinder your manufacturing workflow from achieving its full potential.

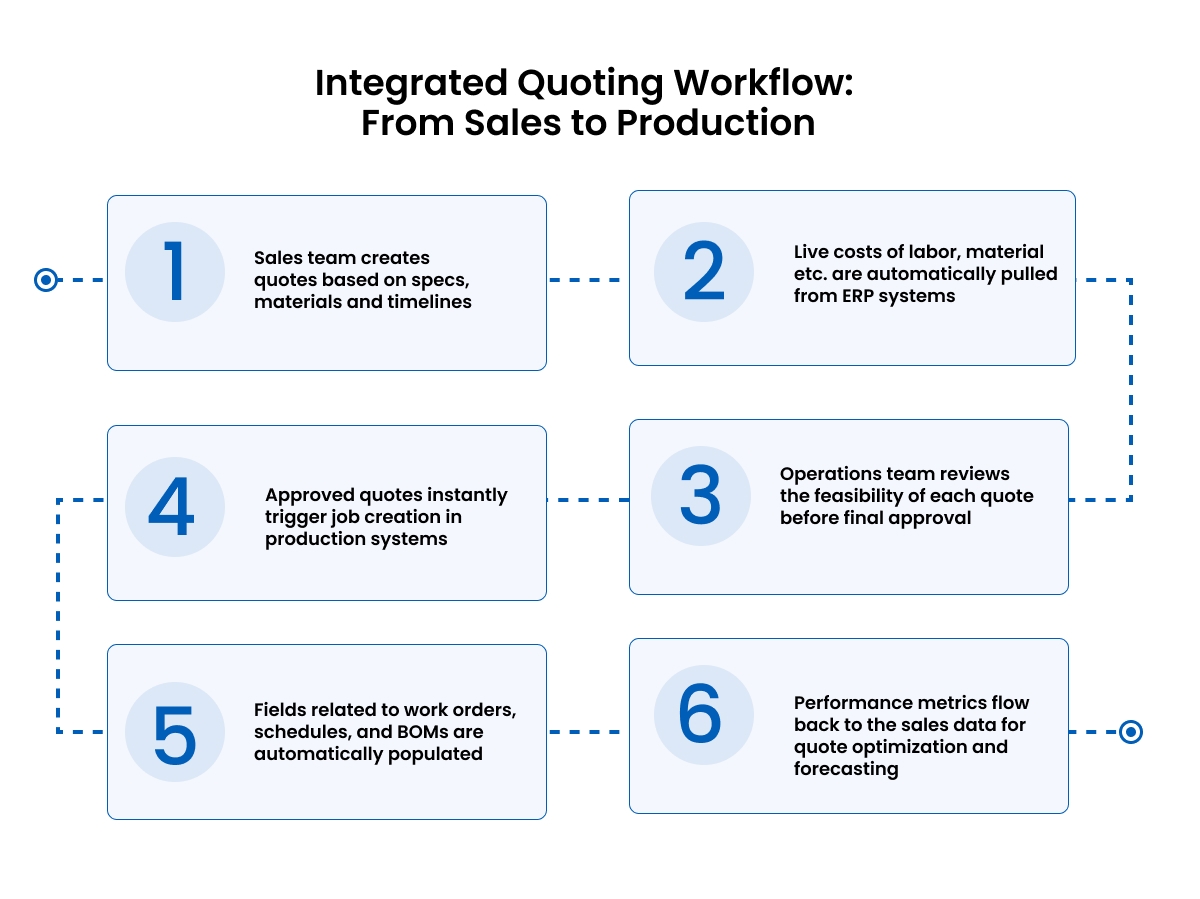

Automation lies at the core of a manufacturing quote management system. From creation and approval to the transference of a finalized quote into the production platform, it automates every single step, thus eliminating manual inaccuracies.

Connection with ERP, CRM, and production systems

An integrated quote system does not treat quoting as a standalone task. Instead, it actively incorporates the input offered by your CRM, ERP, and shop floor systems, so your quotes reflect real-time data without any inaccuracy. It also serves as a single source of truth for every team involved.

Real-time data flow across departments

One thing you need to know about ERP-integrated quoting software is that it is purpose-built for manufacturing. When it syncs to the other platforms in your software suite, it does so to pull accurate data so the feasibility of each quote can be verified before it is sent out.

Furthermore, it also enables real-time pricing updates while handling complex BOMs with ease. That means there is no scope for data duplication or miscommunication across departments. Everyone gets access to the same information, and the flow from quote to job order is truly seamless. The result? More deals won.

Why Integration Matters for Manufacturing Operations

In the manufacturing industry, a quote isn’t just a way to win deals. It sets the stage for production. Sadly, when your sales and operations teams are not on the same page, the quotes delivered to your clients are highly likely to contain small errors, which can multiply and lead to delays, reworks, and lost profitability.

Integrating quoting software can save you from this mess by enabling sales and operations alignment. Let us show you how.

Real-time visibility into costs and capacity

From labor rates and machine availability to raw material costs, integrated quote systems pull live data directly from your ERP and inventory platforms. This helps your sales team generate proposals that are not only free of mistakes but also reflective of real production constraints, thus eliminating chances of over or underquoting.

Synchronized pricing between sales and production

If manual quoting is the norm in your manufacturing company, chances are your sales and operations teams are working from separate spreadsheets. That means either one or both of them have access to outdated data.

A manufacturing quote management system erases this bottleneck by standardizing pricing logic across departments. That means every generated quote features consistent information pulled from the same verifiable database. Thus, each variable is automatically synced in real-time to protect your company’s profit margins.

Seamless order handoff and tracking

As soon as a quote is approved, custom software instantly transfers the specifics of the job to your company’s production platform without any duplicate data or missing specs. This allows your operations team to start work promptly. This kind of complete transparency and clarity during handoff minimizes delays and miscommunication between teams.

Better forecasting and resource planning

With detailed and accurate production and quoting data available at your fingertips, you gain real-time insight into the demand trends and patterns of your business. For your operations team, this data is very valuable as they can use it to accurately forecast workloads, material needs, and capacity utilization. Meanwhile, your sales team can use the same data to convince clients with winning quotes more confidently.

The synchronicity integration brings is the real champ here as it turns your quoting process into an engine of accuracy, transparency, and collaboration.

5 Ways Integrated Quoting Software Bridges Sales and Operations

The lack of a universal truth between your sales and operations team can turn even the simplest of quotes into a cumbersome process. Sales and operations alignment with the help of a dedicated quotation making software is the only way to bridge the data gap and create a shared ecosystem where every department has access to the same real-time information.

Here is how it can overhaul your quote creation workflow for the better:

Centralized data sharing

When scattered spreadsheets and outdated pricing are out of the equation, accuracy reigns supreme. That is exactly what happens when ERP-integrated quoting software unifies data related to sales, engineering, and production. Teams get access to the same information, and misquotes become history.

Automated cost calculations

Even if your sales team is made up of maths wizards and Excel pros, manual methods can still lead to calculation errors. Material, labor, and overhead costs tend to vary. That means quotes require live ERP and MRP integration to reflect current prices that protect your business’s margins.

Collaborative quote approvals

For a quote to receive the stamp of approval, it needs to pass through the hands of your sales and operations teams at the very least. A custom quote system comes with a built-in approval workflow so each team can review proposal drafts, thus eliminating the scope of revisions.

Dynamic production scheduling

Once a quote is approved, your production scheduling system takes over to kickstart the job your company just clinched. The only difference is that with an automated quote-to-production workflow, data from approved quotes is automatically fed into your production platform without the need for human intervention. This, in turn, automates the process of job order and task timeline generation, thus boosting overall efficiency.

Analytics for continuous improvement

With every quote and job logged, analysis and comparisons become easy. Stakeholders and managers can use this data to track critical KPIs such as quote-to-production accuracy, conversion rates, and turnaround times. It also helps in identifying bottlenecks so future quoting cycles can be optimized.

Quick Integration Health Checklist

Want to know if your brand-new custom quote system is performing as well as it should? This quick checklist will help you:

- All departments in your manufacturing firm now have access to the same data

- Different systems your company uses sync automatically with your new quoting platform, including ERP

- You now have standardized approval workflows in place for quotes

- Approved quotes with accurate data form the basis of production scheduling

- You can track key KPIs to gain a deeper understanding of quoting accuracy, response times, and efficiency gains

Manufacturing Efficiency Through Integration

Access to the same verifiable data does not merely mean your sales and operations teams are finally on the same page. It means measurable results are now a reality. You can actually witness the transformative effect of an integrated quoting software – whether it is real-time production quoting, improved coordination, or increased focus on throughput.

Reduction in quote cycle times

Remember the time when quoting used to take days? You cannot, right? That’s how profound the effect of custom quote systems can be. They shorten the quote cycle from days to a few hours – all without compromising on accuracy. That kind of speed can boost your business’s competitiveness in the market.

Improved on-time delivery rates

Quotes that sync directly with production schedules can significantly improve your job fulfilment rates. Last-minute errors and delays are reduced to zero when your operations teams receive clear and complete data upfront.

Enhanced sales forecast accuracy

The switch from reactive to proactive forecasting is possible only when your quotes and production data are available on the same platform. This gives key stakeholders access to valuable data, which they can use to analyze quote win rates, capacity utilization, and pricing trends from a single dashboard.

Custom quote systems can help you solidify your position in the manufacturing market, giving you a solid edge over your competitors. If you want to solidify your position further in the market, it makes sense to embrace the latest trends of the manufacturing sector. Especially the ones that apply to your business.

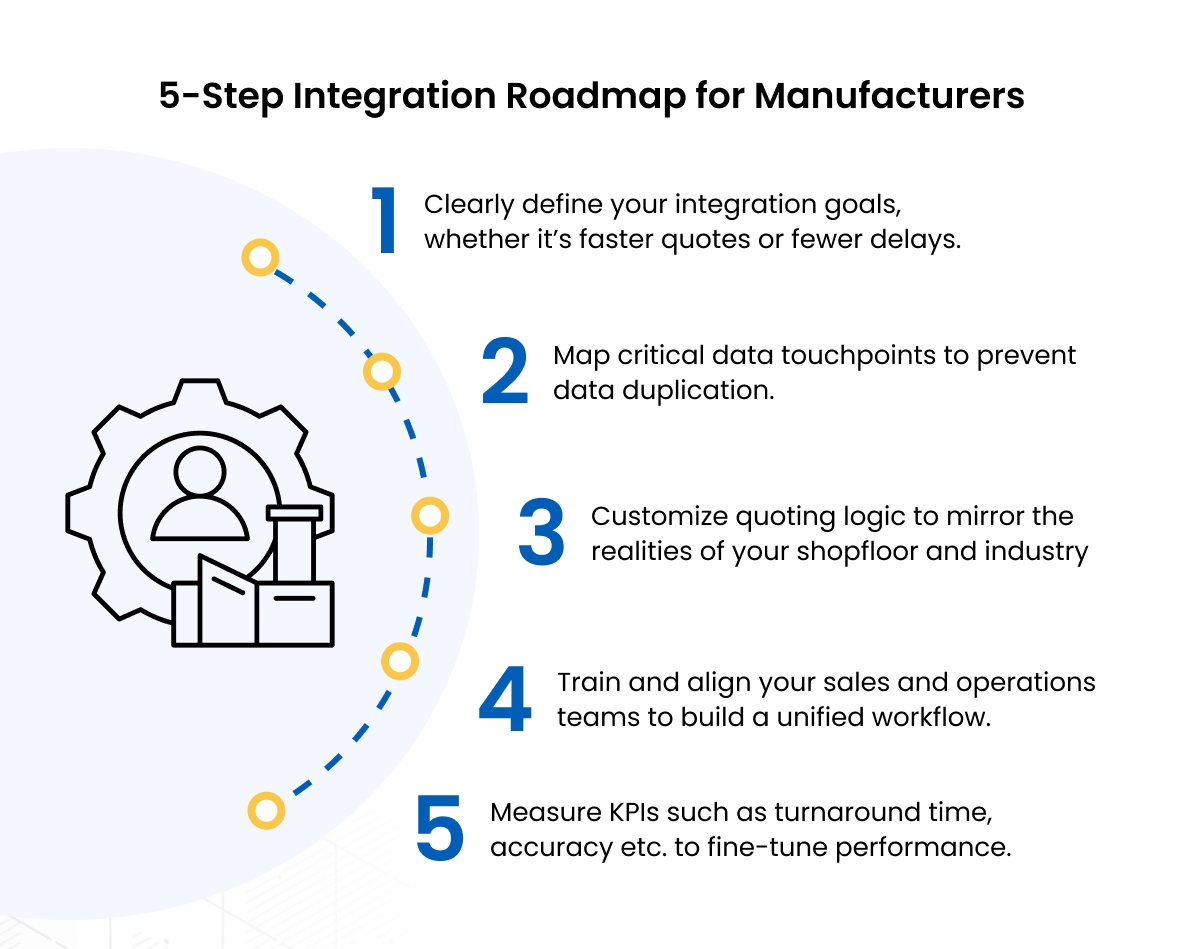

How to Successfully Implement Integrated Quoting Software

It is wise to approach the implementation of custom quoting software as a strategic move rather than a simple tech project. Their transformative effect alone justifies formulating an implementation plan that is poised for success – especially if you prepare thoroughly and lead with clarity.

Step 1: Define integration goals and departments involved

Contrary to popular belief, choosing a platform or a vendor is not the first step. Defining your goals is. Figure out what you wish to achieve with a manufacturing quote management system. Is it faster quote approvals, improved cost tracking, sales-to-shopfloor visibility, or all of them? Once you sort out your objectives, make sure your sales, engineering, and operations team share your vision.

Step 2: Map data touchpoints between quoting, ERP, and CRM

Chart the flow of information between the different systems your manufacturing plant uses. Outlining the journey of critical data, such as materials, BOMs, customer information, and pricing logic, will help you understand where handoffs occur so you can minimize issues such as data duplication while keeping things clean and in sync.

Step 3: Customize software around your production process

Do not fall into the trap of off-the-shelf tools. They do not have what it takes to replicate the realities of your operations. Tailored integration, on the other hand, accurately reflects every metric important to your plant – be it machine rates, material lead times, or anything else.

Step 4: Train cross-functional teams on new workflows

A system overhaul can be tough on your teams. You can mitigate fears with the help of proper change management. Start by offering your sales and operations teams instructions on how to use the new software. Provide them with knowledge materials, have pilot users, gather feedback, and scale progressively so your team can catch up in a hassle-free manner.

Step 5: Track key performance indicators post-launch

Once your team is used to the new system and its automated quote-to-production workflows, measure its impact with the help of useful KPIs such as quote accuracy, turnaround time, order conversion rates, and shopfloor utilization. Continue optimizing your quoting process to ensure long-term ROI.

Quick Implementation Checklist

Here’s an easy checklist to help you stay on track with your integrated quoting software implementation journey:

- Clearly define integration scope and goals

- Verify compatibility with your existing ERP and CRM software

- Have a proactive plan in place to train your teams

- Define baseline metrics pre-launch to measure success post-implementation

- Gather user feedback and continue refining your quoting process

Final Word: Why Vestra Inet’s Custom Quote System Is Built for Integrated Manufacturing Workflows

An integrated quote system is a driver of efficiency and profitability for any manufacturing business. At Vestra Inet, we understand the gravity of its role. We know that quoting is not a standalone task. It is a collaborative effort that requires the valuable input of both your sales and operations teams. That is why our custom quote is built to link all relevant departments.

Integrating seamlessly across your entire operation, it connects sales, ERP, and production scheduling data in real-time. The result? Every quote is replete with correct costs, capacity, and material prices. Plus, the approval path is straightforward, in sync with your company’s processes, and free of delays, which means approved quotes can be instantly turned into production-ready job orders.

So if you want a system that does things differently, more efficiently than generic CPQ tools, turn to us. Vestra Inet is a leading provider of custom manufacturing quote systems in Ontario that adapt to your pricing logic. Contact us to get fully customizable solutions that allow you to create quotes with greater control, clarity, and confidence.

FAQs

What is integrated quoting software?

Integrated quoting software is a system that is designed to connect the process of quote creation with a company’s ERP, CRM, and production tools to enable the seamless flow of real-time data between its sales and operations teams.

How does quoting software improve manufacturing efficiency?

Custom quote systems can enhance manufacturing efficiency by automating critical processes such as cost calculations, data syncs, and quote handoffs. Each of these eliminates manual inefficiencies that can slow down production.

Can quoting software integrate with ERP and CRM tools?

Yes, of course. Sophisticated custom quoting software, such as the one offered by Vestra Inet are built to plug into existing tech stack so your business does not have to suffer from unnecessary halts.

What are the benefits of connecting sales and operations systems?

The major benefits of syncing your sales and operations systems include shared visibility into unified data, faster approvals, accurate pricing, and realistic delivery timelines.

How long does it take to implement an integrated quoting system?

Implementation timeframes vary, but you can go live within a few weeks if you choose a reliable vendor and opt for phased onboarding.

Author Bio

Andrey Wool

Helming the operations at Vestra Inet, Andrey has over 20 years of leadership experience in the ERP industry. Having successfully launched 550+ software projects across a diverse set of industries, Andrey continues to transform the way businesses function with pioneering custom software solutions. His in-depth knowledge of sectors such as manufacturing and distribution has helped him curate actionable solutions that eliminate bottlenecks and pave the way for sustainable growth.