Optimizing Wellington Perforated Inc.’s Perforated Sheet Production With Vestra Inet’s Custom Product Management & Scheduling Software

Wellington Perforated Inc. is a leading manufacturer and distributor of perforated metals in Canada. Specializing in sheets and plates, they have over 30 years of experience in the industry. Equipped with advanced machinery and providing custom fabrication options, Wellington Perforated Inc. also has a fully stocked warehouse, offering quick turnaround times for customer orders.

- Custom Production Management Software

- Custom Scheduling Software

- Custom Dashboard

A leading provider of high-quality perforated metal products, Wellington Perforated Inc. operates in a fast-paced environment where fulfilling customer demands in an efficient and accurate manner is highly critical. This requires them to manage both the inventory at their warehouse as well at the orders they get. Ensuring there is no gap between the two is a crucial factor in successful order fulfillment.

Wellington Perforated Inc. faced certain issues in managing their complex production processes. Increasing demand, growing number of custom orders, inefficient scheduling processes, which could lead to production delays as well as the gap between customer orders and availability of materials were some of the challenges that needed to be dealt with promptly.

What Wellington Perforated Inc. needed was a centralized, automated system to streamline their daily operations as well as enhance communication, resulting in an improvement in overall productivity. They needed custom software solutions tailored to their specific needs with features such as custom production management, scheduling as well as a centralized dashboard to manage it all.

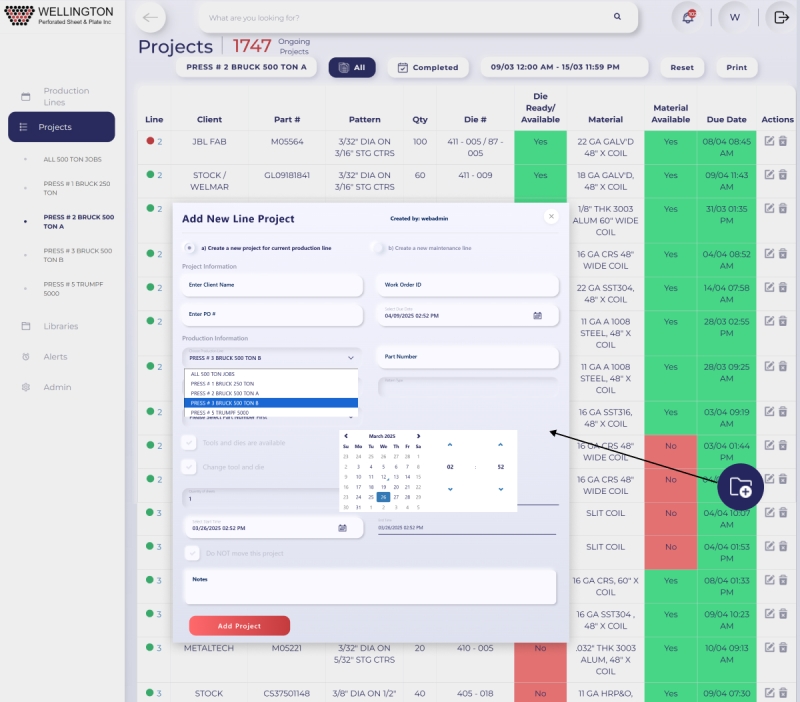

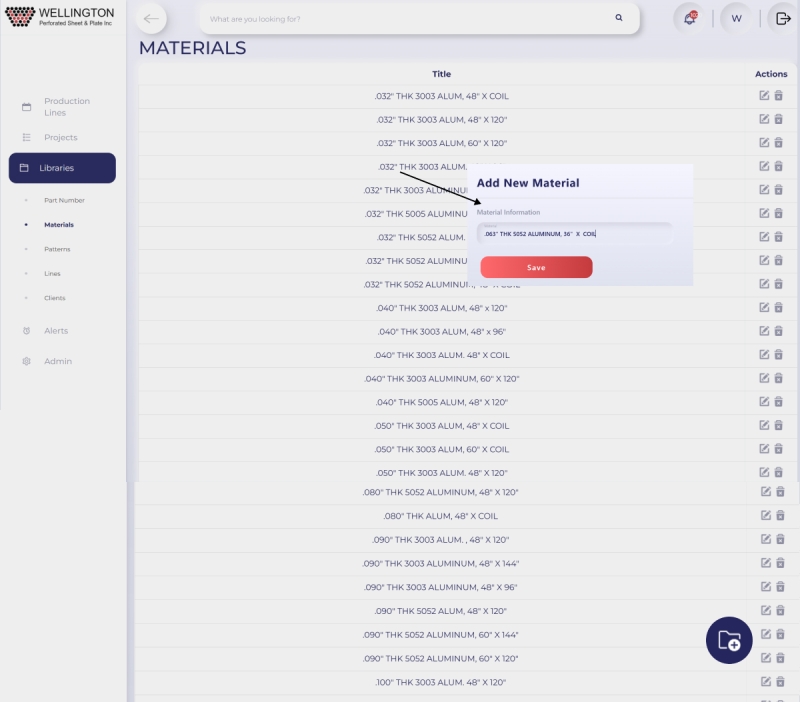

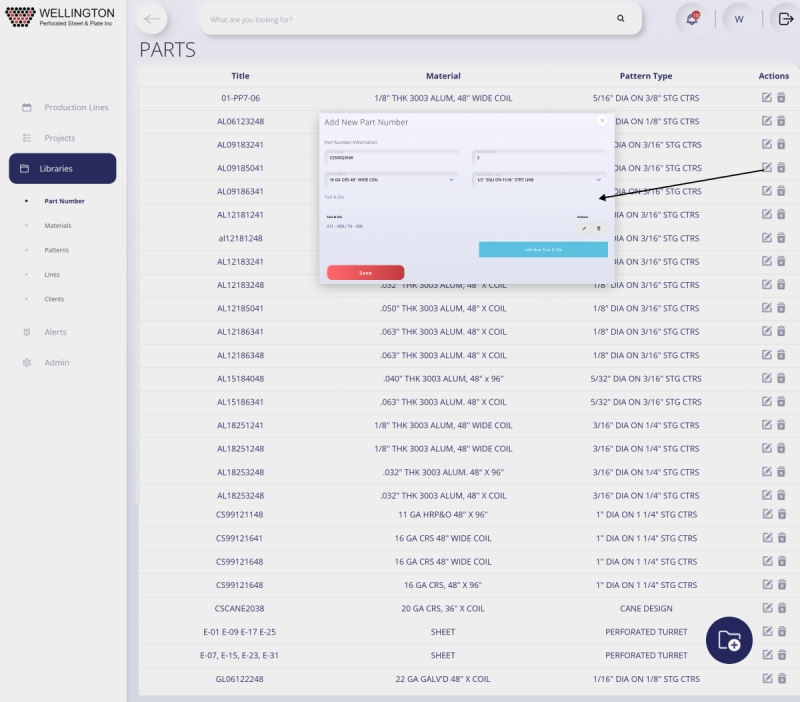

At Vestra Inet, we created custom software for them that had all the features they needed. Starting with an advanced production management system that helped the company organize its production processes by keeping track of the materials available to successfully fullfil orders received. It also allowed them to get real-time updates on production progress, allowing managers to identify as well as quickly resolve any bottlenecks that may arise. Integration with existing systems and machinery further helped in the collection of data that was instrumental in enhancing production efficiency. Finally, order grouping based on shared requirements such as metal type, delivery location or requested patterns further streamlined the production and shipping process.

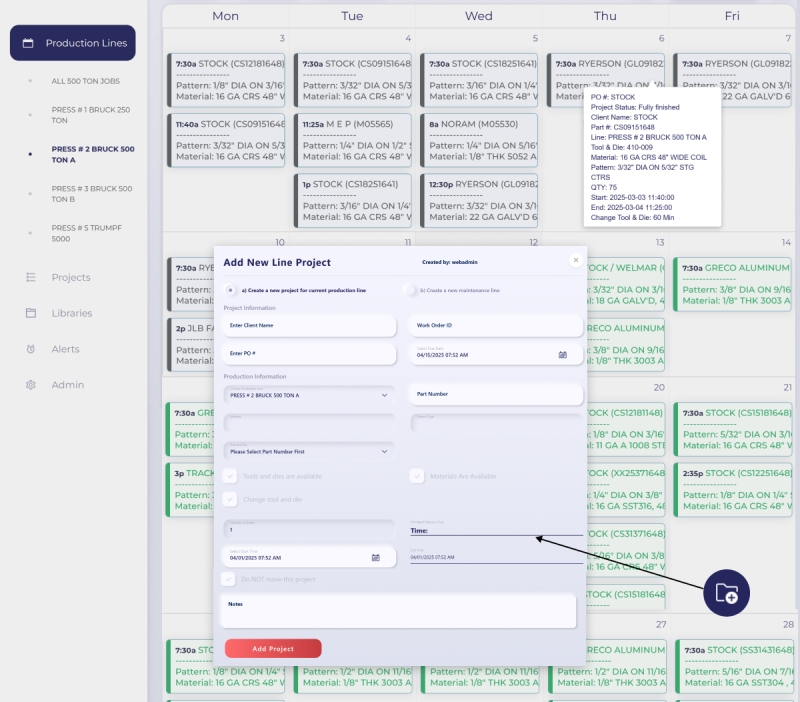

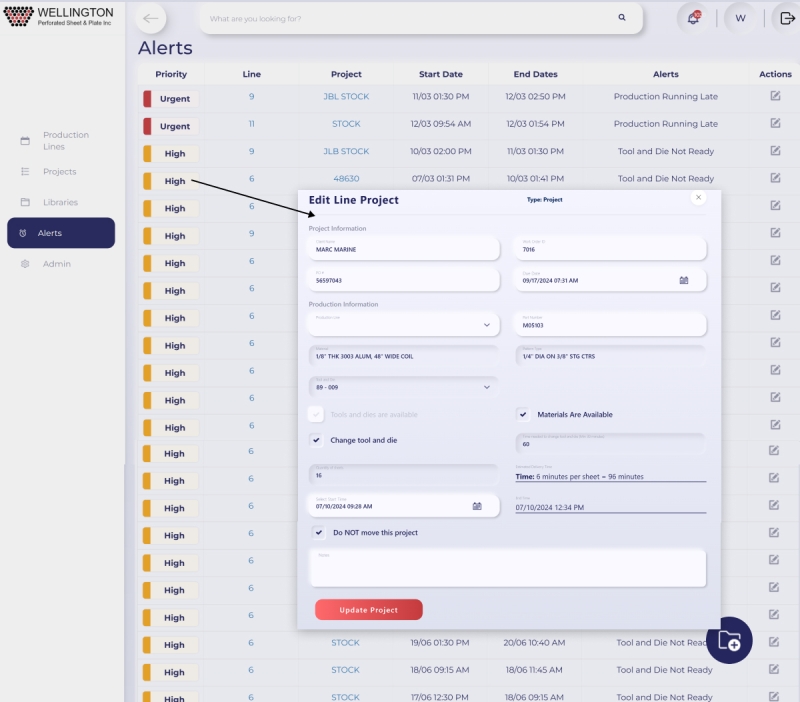

Part of the software we designed for them was a robust scheduling system. Designed to tackle the challenge of managing the company’s calendar, the system helped the company prioritize critical tasks as well as move items around quickly to meet changing demands. Alerts for potential delays allowed for proactive decision-making while automatic schedule adjustment based on resource availability improved order fulfillment and customer satisfaction.

Lastly, a centralized dashboard offered the company a comprehensive overview of its different processes such as delivery schedules, order statuses, production metrics and inventory levels, allowing stakeholders to track the day-to-day operations of the company and make adjustments as and when necessary.

Our custom software helped Wellington Inc. overcome all of the challenges they faced in one shot. It increased efficiency of their daily operations by providing them with exactly what they were looking for. A consolidated software that offers productive features which are tailor-made to their unique requirements instead of multiple software that perform the same function and unnecessarily complicate simple tasks.

Manufacturing Management Software

- Full control of production cycle

- Automation of multiple production stages

- 360° view of all production processes

- Flexible scalability

The principal feature of custom-designed production management software is that it is built to adapt to your existing manufacturing processes. It increases the operational efficiency of complex multi-stage production processes by collecting and consolidating data across all units involved in the manufacturing process into one system. Production Management Software allows for centralized control of all manufacturing stages leading to more optimized production flow, saved costs and increased profits. With production management software your work will be smarter, not harder.

Forecasting Software

- Accurate sales and stock level predictions

- Full reporting functionality to provide year-over-year proof of benefits

- Synchronization with key data collection systems for highly accurate predictions

- Analysis of variables and aspects when forecasting

Specialized sales and supply forecasting software is developed to streamline supply chain and logistics management. Complex algorithms support the analysis of multiple data sets to build accurate predictions for supply and demand on a national scale. Items can have a specified minimum stock level in various locations. The system accurately predicts stock levels over a future time period and allows automatic purchase order creation to replenish levels. Additionally, a custom dashboard provides a snapshot of forecasts and gives access to customizable reporting tools.

Performance Tracking and Reporting Systems

- Custom report generation

- Adjustable analysis parameters

- Analyze data from multiple sources

Analysis of performance at all stages including production, sales, shipping, and more is critical to success. Performance tracking systems were designed to specifications and implemented to present detailed analytics data to clients. This data could be automatically recorded over time for multiple variables including process efficiency, sales, cost of production, and more and presented as automatically generated reports. Custom parameters could be set to gather data regarding specific processes.