Elevating Siltech's Chemical Manufacturing with Vestra Inet's Custom Forecasting and Process Optimization Solutions.

Siltech is a chemical manufacturing company situated in Ontario Toronto specializing in organo-functional silicone compounds and resins. These silicone products are highly customized according to the applications and requirements of the customer. The company serves various industries ranging from personal care, automotive, oil and gas, and agriculture to paper, 3D printing, and more. With two plants located in Toronto and Mississauga, the facilities are equipped with state-of-the-art pressure reactors, thin film evaporators, and more which are utilized in equilibration, hydrosilylation etc. Apart from their excellent research and development in manufacturing organo-functional silicone compounds, Siltech also focuses on optimizing production techniques.

- Production forecasting

- Production process automation and optimization

- Sequence management

- Reporting system

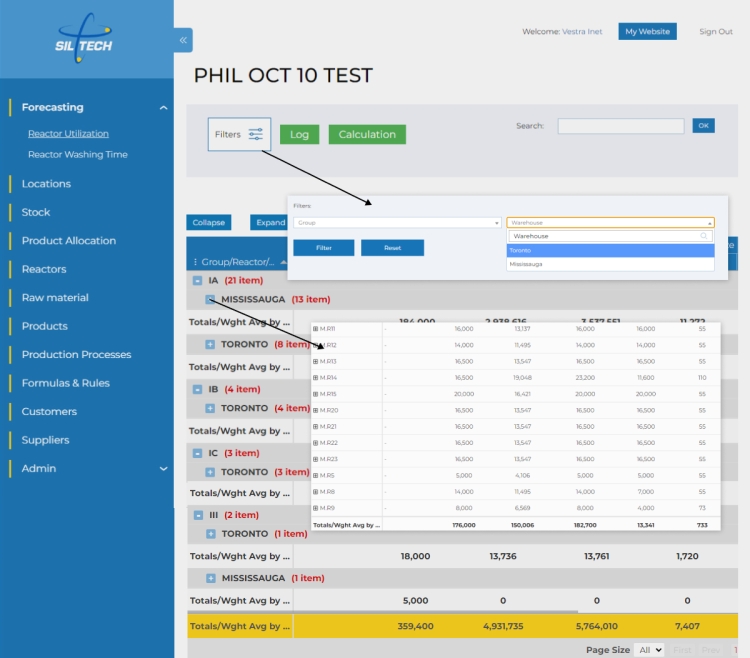

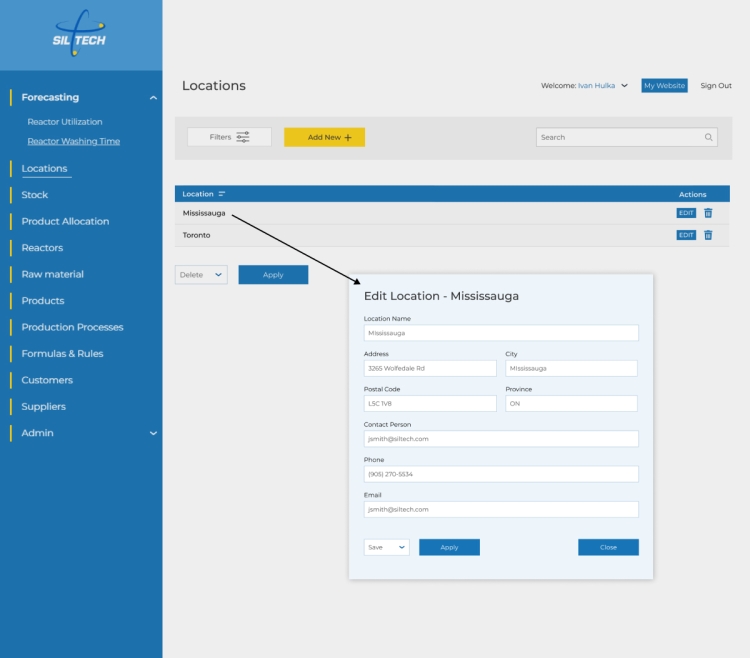

Siltech specializes in organo-functional silicone compounds in resins, which are manufactured in its two primary facilities in Toronto and Mississauga respectively. Each of these facilities has numerous tanks where the chemical compounds are mixed and prepared to create the desired product. The company required a process to accurately determine and deliver the required quantity of a particular resin on a stipulated date to make the manufacturing process more streamlined.

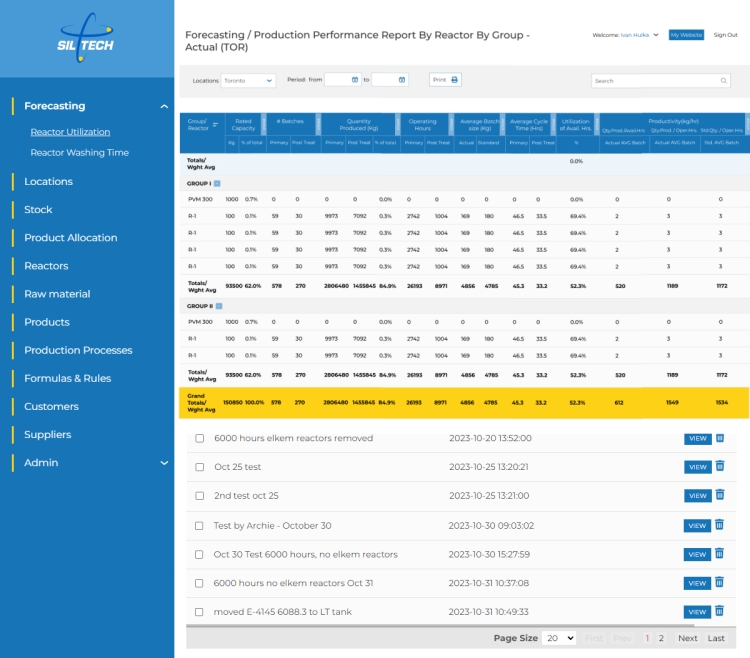

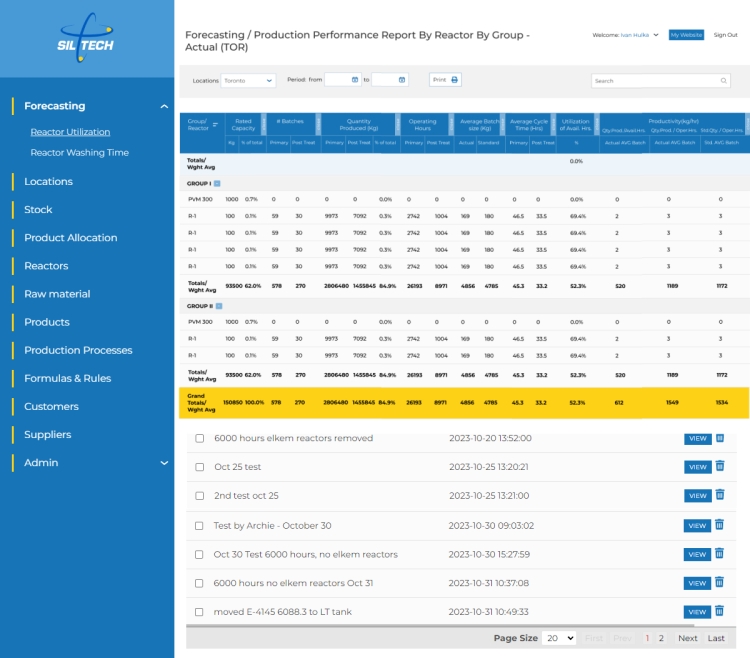

This was made possible with the help of a production forecasting system that takes into account the previous work order history of the company to predict how much of a particular resin or product is required to be produced and delivered at a particular date. It also considers the current capacity of the facilities before making detailed predictions. With these variables, this forecasting system manages to make predictions with 97 percent accuracy, significantly improving the production process.

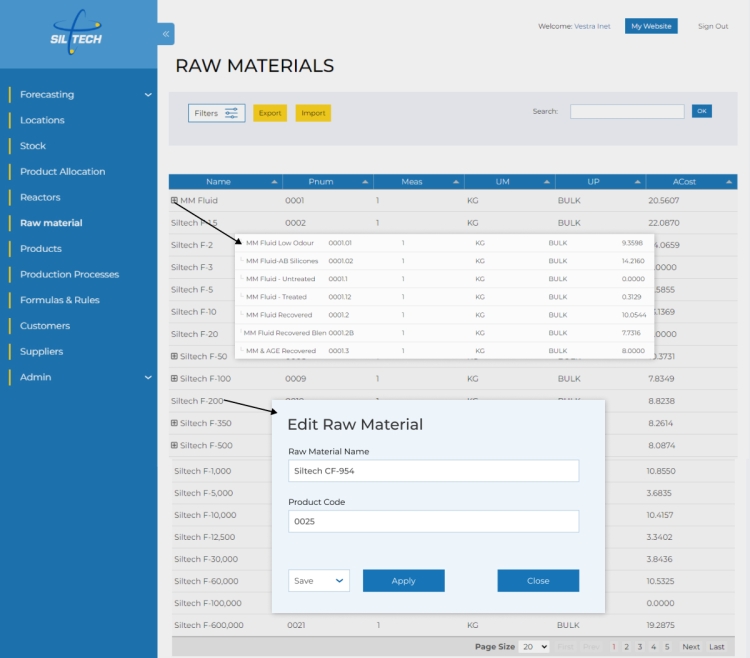

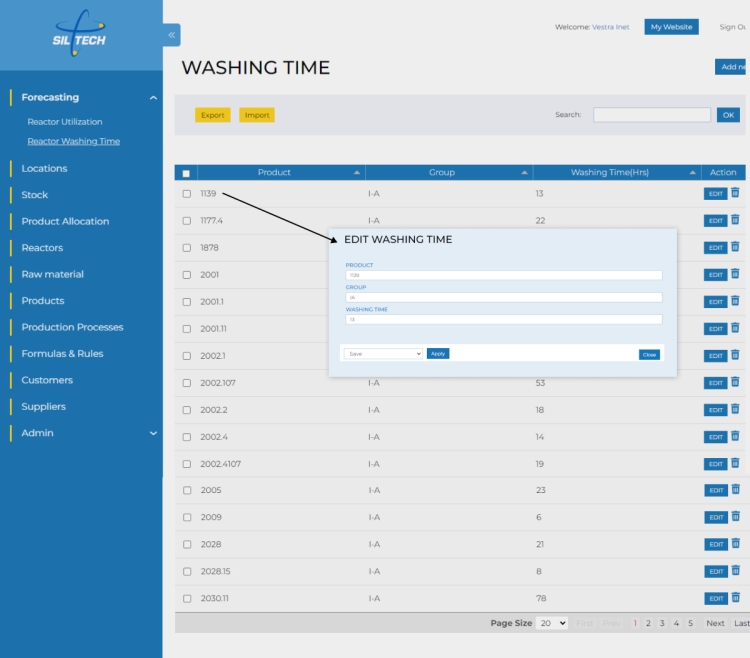

Apart from predicting the quantity of the given resin/product, Siltech also required a system to accurately allocate the production process for the most optimal results. Since the company has multiple tanks of different capacities in their facilities in Toronto and Mississauga, manually examining and allocating tanks before production was an inefficient option. To mitigate this, a production monitoring module was also added wherein the system can accurately assign the right facility and tank based on the current work order. This was made possible by monitoring the current production setup in their multiple facilities, making the process automated and optimal.

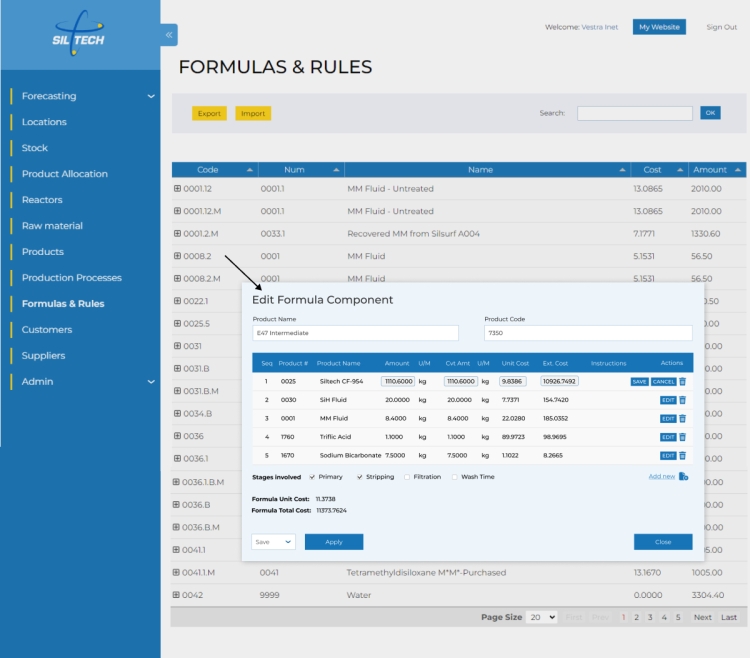

Furthermore, due to the complexity of handling chemicals, resins and silicone-based products, the sequence of adding chemicals during manufacturing is also a critical factor. Hence, Siltech also had a requirement for a system wherein the right sequencing of constituent products is already built in. For this, a sequence management feature was also added to the system, which takes the previous work orders into account for determining the right sequencing of chemicals. Thus, the combination of production forecasting system, process automation and sequence management enables Siltech to deliver high-quality resins and silicone-based compounds without delays while simultaneously optimizing the production process.

Lastly, the company also required an effective way to create and manage reports and work orders. For this, a standard reporting system was also added atop the aforementioned features to facilitate faster and more accurate report generation.

Thus, the employees Siltech only have to enter a new work order, and with the aid of the forecasting system, production management and optimization, sequence management, and reporting, the entire manufacturing process becomes highly automated and streamlined, enabling the company to increase its production quality, reduce or eliminate delays and lastly, improve its market share in the organo-functional silicone compounds sector.

Type of Systems Used in Project

Manufacturing Management Software

- Full control of production cycle

- Automation of multiple production stages

- 360° view of all production processes

- Flexible scalability

The principal feature of custom-designed production management software is that it is built to adapt to your existing manufacturing processes. It increases the operational efficiency of complex multi-stage production processes by collecting and consolidating data across all units involved in the manufacturing process into one system. Production Management Software allows for centralized control of all manufacturing stages leading to more optimized production flow, saved costs and increased profits. With production management software your work will be smarter, not harder.

Forecasting Software

- Accurate sales and stock level predictions

- Full reporting functionality to provide year-over-year proof of benefits

- Synchronization with key data collection systems for highly accurate predictions

- Analysis of variables and aspects when forecasting

Specialized sales and supply forecasting software is developed to streamline supply chain and logistics management. Complex algorithms support the analysis of multiple data sets to build accurate predictions for supply and demand on a national scale. Items can have a specified minimum stock level in various locations. The system accurately predicts stock levels over a future time period and allows automatic purchase order creation to replenish levels. Additionally, a custom dashboard provides a snapshot of forecasts and gives access to customizable reporting tools.

Performance Tracking and Reporting Systems

- Custom report generation

- Adjustable analysis parameters

- Analyze data from multiple sources

Analysis of performance at all stages including production, sales, shipping, and more is critical to success. Performance tracking systems were designed to specifications and implemented to present detailed analytics data to clients. This data could be automatically recorded over time for multiple variables including process efficiency, sales, cost of production, and more and presented as automatically generated reports. Custom parameters could be set to gather data regarding specific processes.